Embrace the Cloud - Mid-term Report for the 1st Year of L&K Engineering’s Cloud Application

date:2020-07-03 browser:72

At present, the new generation of information technology, represented by 5G, the Internet of Things, big data and artificial intelligence, is developing rapidly, leading a new round of scientific and technological revolution and industrial transformation. More and more engineering construction enterprises realize that information construction is an important means to enhance the core competitiveness of enterprises and realize the modernization of enterprise management. Enterprise informatization is a management practice, so we must adhere to coming from practice and being applied to practice, and the repeated circle of practice - improvement - practice again - improvement again to realize a spiral rise.

Since the introduction of SAP’s ERP system from Germany in 2008, and the introduction of OA platform in 2012, L&K has e-purchased the equipment materials and labor subcontracting at the project sites, thus carrying out the first informatization practice in material and worker resource supply process. In 2016, we independently developed the Huanan Cloud management module, which is an informatization practice of the safety management during the project construction, and optimized it again in 2018 to meet the management requirements of the construction site and the corporate headquarters. In 2019, we successively developed functional modules such as schedule management, quality management and personnel organization management to carry out informatization practice in the construction process management in an orderly manner, and made certain achievements. Mao Zhihui - President of L&K formally proposed the year 2020 as the first year of L&K’s application of Cloud platform for project management at the 2019 year-end dinner and award ceremony.

Over the past six months, we have summed up our practice and application experience of the project management cloud platform in such projects as Wuhan Hongxin, Mianyang Huike and Kunshan Huatian. In cooperation with the colleagues at the project site and the supporting departments of the company’s headquarters, we not only preliminarily realized the goal of "cloud" management of all projects under construction in 2020, but also actively added the management execution data of the projects above the designated scale in 2018 and 2019.

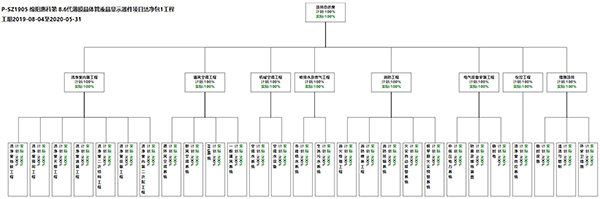

In terms of the organization and management of project personnel, the project leader should maintain the entry time and departure time of the host engineers of each system in the basic data module of the project cloud platform after the project is put on file. The headquarters of the company makes monthly statistics of the released manpower of all projects of the company through the system statement. Such manpower will be identified by the management and effectively put into new bidding business or execution projects. Through this mechanism, the headquarters of the company realizes dynamic management over the project personnel.

In terms of equipment material purchase and labor subcontracting, the original PR/PO Control List EXCEL has been uploaded to the “Cloud”. Apart from the fact that the project director maintains the planned dates of turnover nodes in all the purchase requisitions, the system can also automatically match actual turnover date of the turnover nodes in the purchase requisitions, actual order date filled by the purchase operator and the actual arrival date and installation date filled by the project director. When there is a large deviation between the actual value and the planned value, the system can return the red words or figures on its own so that the manager can quickly focus on the purchase requisition with a large anomaly and take timely intervention or remedial measures.

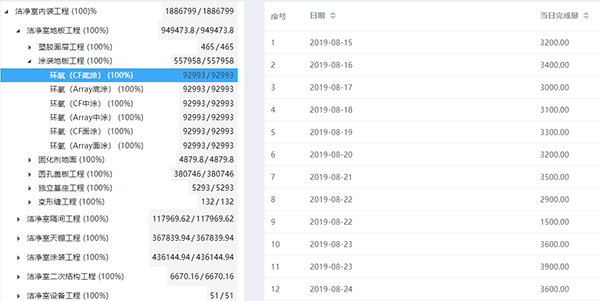

In terms of project progress management, for the projects above the designated scale, the starting time and completion time of standard work items of each system will be maintained on the project cloud platform, and the system engineers will report the completed work amount on the platform on a daily basis. The work items at the bottom of the system are carried out in accordance with the construction process, so as to ensure that the engineers will fill the completed work amount that day as there is actual construction on the site.

The cloud platform can calculate the current system's accumulative progress in real time through the preset program, and compares it with the original schedule. If there is any lag, the system will automatically return a warning with red words or figures, and the manager can click the system with abnormal progress to check the next level of work item until the main reason for the deviation is found. This also helps the manager to find the problem early and make improvement plan, and finally execute the system until the problem is solved.

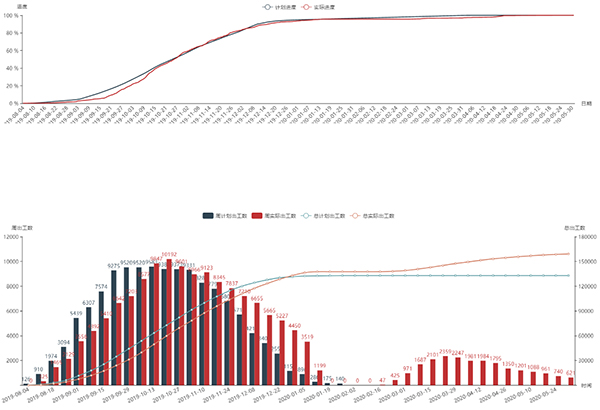

In terms of worker presence management, we require that an on-line work safety log should be filled for all projects with more than 20 employees present, and the engineer need to count the number of employees present in each system on that day. Besides, at present, large projects have been equipped with a worker code scanning system to scan the code of the participating workers at the daily presence toolbox meeting, and the cloud platform will make real-time statistics of the actual number of workers present of each system, each contractor and each type of work of the project that day. The project cloud platform compares the presence information in the work safety log with the presence information collected by the code scanner to ensure the correctness of the presence data every day. Because the information of all workers on site is collected and entered into the system during the on-site safety training, it can be confirmed that the workers have been trained and recorded in the real-name registration system when actually entering the site for construction, and the scanner can display the workers' photos on site in real time to help the engineer check whether they are the workers themselves.

When the construction progress and presence data are available in the project cloud platform, the system chart automatically presents the planned value and actual value of the current construction progress, the planned value and actual value of weekly presence and the planned value and actual value of S-curve. The manager can quickly identify whether the lag of the current construction period is related to the number of workers present through the chart. If the manpower is insufficient, the manager can quickly issue the instruction to increase the manpower, so as to avoid the problem that the delayed construction schedule cannot be solved.

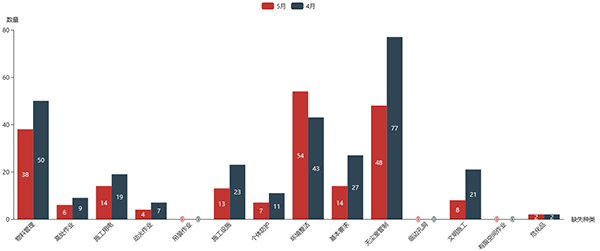

In terms of environment, health and safety management, the safety engineer will go to the site for environment, health and safety inspection every day, supervise the implementation of all on-site operations in accordance with the regulations for environment, health and safety management, report the defects of environment, health and safety found that day to the Project Cloud Environment, Health and Safety System in a timely manner, clarify the person responsible for the rectification, the rectification requirements and the rectification deadline, and continue to track the rectification situation. The defect statistical chart can be generated at any time in the Project Cloud Environment, Health and Safety System to provide a basis for project and company to make decisions about environment, health and safety management.

The environment, health and safety manager can grasp which categories of defects are on the rise through the statistical analysis report of defects, so that they can intervene in the categories with a fast rising rate in time and pay more attention to the categories with a large proportion of defects. Through these management methods, we strive to avoid the occurrence of potential dangers, extinguish the existing dangers in time rather and stop them from continuously expanding, and finally achieve the safe production of the project.

In addition to the above project human resources management, purchase requisition management, schedule management, worker presence management and environment, health and security management, we are also continuously developing functional modules such as fund management, material management and file management. Among them, the payment request information, project cash flow statement and project receipt confirmation under the fund management are already in use, and the achieving rate of project payment return plan will also be put into use in the near future. The material management module is also on trial in Ningbo Nanda, Kunshan Huatian and Wuhan Huaxing, and it is planned to be put into use in new contracted projects after July. In the project data management, the construction photos and engineering technical review have been put into use; the detailed outgoing and incoming documents of projects is currently in trial operation.

Of course, a complete integrated management system for the project site contains a wide range of functional modules and related stakeholders, but the application modules developed by L&K are only limited to the demand for management informatization inside the company. For the project management platform based on Internet technology and cloud computing technology, on the one hand, we should constantly practice and sum up experience; on the other hand, we should make L&K’s employees gradually accustomed to the application so as to get more development demands, eventually forming a set of project management system which is suitable for our company and can also be applicable to construction enterprises within the industry and be popularized.

Finally, I would like to express my thanks to all the colleagues who have participated in the promotion and practice of the project cloud platform, and hope that L&K’s project management cloud platform can advance steadily and become more and more practical, and become a great management tool for project executives and managers.